Nike Rebuilds, H&M Automates, China Reimagines

Nike reignites its innovation engine under Elliott Hill; H&M backs AI-powered textile sorting to scale circularity; and Changshu transforms from manufacturing hub to tech-fashion pioneer.

Nike Reignites Innovation Engine Under Elliott Hill

After years of stagnation and leadership churn, Nike’s new CEO - and former intern - Elliott Hill is rebuilding the swoosh’s creative muscle (paywall). At a two-day Beaverton showcase, Nike unveiled Project Amplify, an exoskeleton-in-a-shoe that boosts stride power; Nike Mind, neuro-responsive footwear that calms the brain; and Project Milano, an inflatable jacket debuting under a revitalized ACG line. Hill has also reinstated Nike’s sport-based R&D structure, rebuilt retailer relationships, and doubled down on global expansion.

Why it matters: Hill’s turnaround isn’t just about new tech, it’s about undoing a lost decade of over-optimization. By reversing Nike’s direct-to-consumer overreach and re-empowering its innovation teams, Hill is re-humanizing a brand that had become algorithmic. It might prove to be the playbook for how creative companies recover after consulting-era efficiency drives.

https://www.fastcompany.com/91426902/thank-god-nike-is-feeling-like-nike-again

H&M Invests in Reverse to Scale AI Textile Sorting

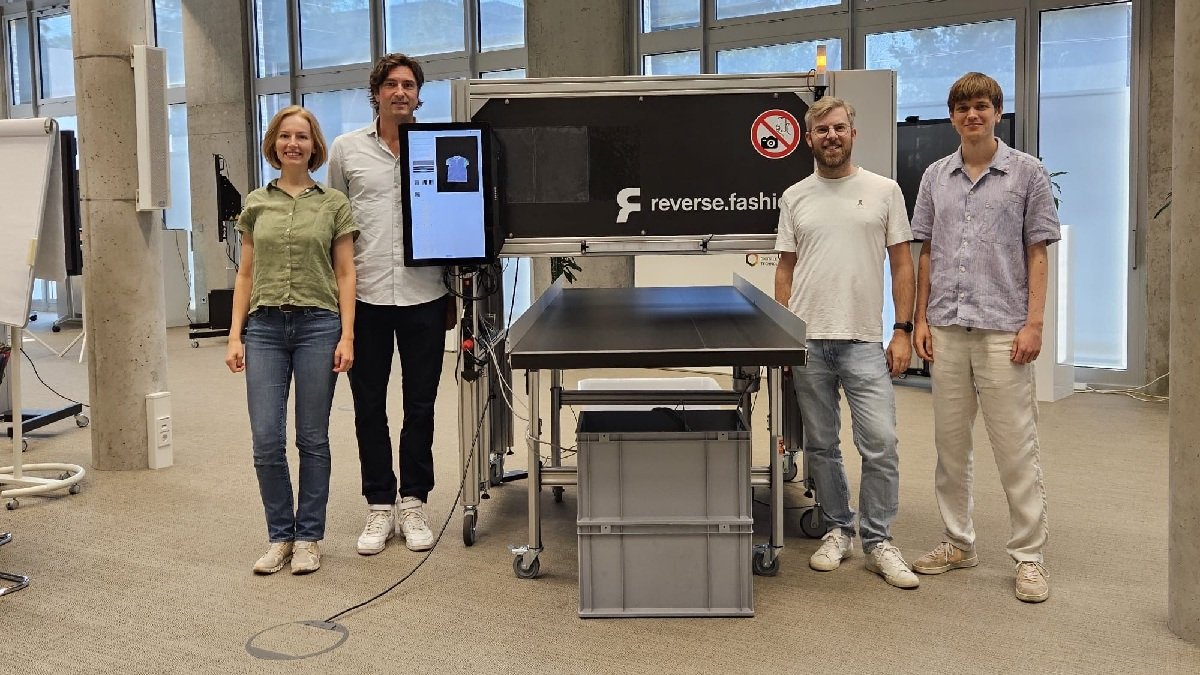

H&M has joined the pre-seed funding round for Berlin-based startup Reverse Fashion, which is developing AI-driven technology to automate the sorting of used textiles. Founded in 2024, Reverse combines image recognition and RFID to identify garment materials, enabling faster, higher-quality sorting for reuse and recycling. The investment, alongside venture capital firm Kisora, will help accelerate the company’s AI Sorting Partner app and expand its R&D and operations teams.

Why it matters: Textile sorting is one of the biggest bottlenecks in fashion’s circular transition - too slow, too manual, and too costly to scale. By backing automation at the source, H&M isn’t just cleaning up its own supply chain; it’s building the infrastructure the entire resale and recycling ecosystem needs to function at industrial scale. It’s a small stake, but a smart one, a credible systems play rather than a PR stunt.

Changshu Hosts China’s First Tech-Focused Fashion Week

Changshu, long a textile manufacturing powerhouse, is reinventing itself through Suzhou Tech Fashion Week (STFW), China’s first event dedicated to “Technology is Touchable, Fashion is Applicable.” The debut drew thousands of global fashion experts and trade deals, spotlighting how advanced manufacturing and design innovation are converging.

Local giant Bosideng embodies the shift, using AI-driven design and intelligent production to create innovations like its Foldable 3-in-1 Expedition Down Jacket. Backed by local policy and industrial strength, Changshu is turning its supply-chain depth into a testbed for high-tech, high-value fashion.

Why it matters: Changshu’s evolution shows how manufacturing hubs can future-proof themselves by blending design, engineering, and production in one place. Instead of chasing low-cost labour, the city is investing in smarter materials, responsive manufacturing, and local brand development. For the wider fashion industry, it could be a sign that innovation is shifting closer to where clothes are actually made.